3D Printing 2020

Theme: 3D printing: The manufacturing technology that will change the world

“Webinar on 3D Printing and Additive Manufacturing” will be held in Paris, France during May 22, 2020. Major attractions of this event would revolve around keynote presentations, oral presentations and poster presentations. This year we are focusing on the theme “3D printing: The manufacturing technology that will change the world". The term "3D printing" is progressively utilized as an equivalent word for Additive Manufacturing. It transforms digital 3D models into strong solid by structure them up in layers. The innovation was first invented during the 1980s, and since that time has been utilized for rapid prototyping (RP). 3D Printing has been applied in engineering and healthcare since the beginning of 20th century.

For the manufacturing of custom prosthetics and dental inserts, it was first utilized and after that on wards the medicinal applications for 3D printing has advanced essentially. 3D printing is the path towards making cell structures in a limited space using 3D printing innovation, where cell limit and suitability are spared inside the printed construct. 3D printing adds to huge advances in the medical field of tissue engineering by allowing for research to be done on innovative materials called biomaterials. 3D bio printers are streamlined to have the capacity to print skin tissue, heart tissue, and veins among other essential tissues that could be appropriate for surgical treatment and transplantation. This innovation is utilized in the fields of adornments, footwear, mechanical structure, design, engineering and construction (AEC), automotive, aviation, dental and medical industries, education, geographic data frameworks, structural building, and numerous others.

Meetings International (Meetings Int.) is a worldwide leader in delivering top quality conferences, gatherings, workshops and symposia in every single significant field of science, technology and medicine. Since its origin, Meetings Int. has been related with national and global affiliations, corporations and elevated level people, dedicated to have world class conferences and events. Meetings Int. supports broad scope research and friend survey at a broad range of specialists around the world. The key strategic objective of Meetings Int. is to communicate science and medical research between academia, and industry. Through motivating sessions and huge amounts of networking, you will figure out how to be much more nervy and strong than you are presently and allowed to develop your mind, develop your business, and develop your primary concern. We can soothe you of the time and asset depleting components of the occasions that you intend to hold. From wanting to planning, through and through; we will be there to guarantee you take the awards for one more splendid program. We organize conferences world-wide. All major conferences of Meetings International are accredited with Continuing Professional Development (CPD), Continuing Education (CE), and Continuing Medical Education (CME) Credits.

Meetings International recognizes the commitment and amazing work in all fields of academics and research. By recognizing their contribution; Meetings International inspires and motivates scholars, researchers and academics by awarding the Best YRF and Researcher Awards in all academic disciplines and categories along with other specific awards. These awards include prestigious Certificate of Award with other gifts.

To be eligible for the awards Students interested in having their posters considered for the 3D Printing 2020 conference, they must have submitted an abstract of their poster to the conference. The awards committee will consider all posters that relate to the study of public opinion, whether they focus on theory, substantive findings, research methods, and/or statistical techniques used in such research. All posters will automatically be considered for the Poster Awards and the posters will take place in the conference venue and Poster Judges will select the best posters. The winners will be formally announced during the closing ceremony. The winners will receive a certificate awards.

Outstanding Masters/Ph.D/Post. Doc Thesis work presentation Awards

3D Printing 2020 gives the opportunity to young researchers in the different field of conferences. The best participants are selected as per their research abstract before the conference. If you are a young and dynamic researcher than you can join our conferences to explore new idea and research. A panel of judges will select the best YRF. Best YRF will be recognized publicly at the end of the conference. The Best YRF Awards will be given to the most outstanding presentation presented by a participant who has registered under the student category. Undergraduates, Master students, and Ph.D. students will be considered under this category. Selection of the YRF will be made on the basis of the participant contribution in the respective research field each submission will be accepted based on the sessions of the conference. Irrelevant submissions will be rejected. The acceptance and rejection of abstract submissions will be selected by the committee. All submissions will go through a quality checking. Final approved abstract will consider for YRF award.

3D Printing 2020 chooses a relevant keynote speaker to speak at conference. All accepted keynote speakers proposals will be considered for the Best Keynote Speaker Awards. The committee will select a number of candidates for the award among the accepted proposals. The winner will be selected at the conference, taking into consideration both the proposal and the presentation. Best keynote speaker can help to boost motivation, change their way of thinking and make audience energized and inspired. For Keynote the person should be eminent or highly affiliated like Dean, Professor, HOD, Chair persons, CEO, CFO, MD etc. Selection of the Best Keynote Speaker will be made on the basis of the participant contribution and years of experience in the respective research field. Each submission will be accepted based on the quality of abstract and conference theme. Irrelevant submissions will be rejected .The acceptance and rejection of abstract submissions will be selected by the Organizing committee. All submissions will go through a quality checking. Final approved abstract will consider for Keynote award.

3D Printing 2020 believes in recognising our best speaker. The best speaker is selected as per their research abstract before the conference. All winners are determined by a selection panel. This awards are designed to recognise and identify outstanding speakers who have achieved recent extraordinary eminence and success. Being an outstanding speaker means to deliver a message that engages an audience. The outstanding speaker awards will also be given on the basis of organization and professionalism of presentation, communication skills of the presenter and appropriate use of time. Each session will be evaluated separately. For speaker the person should be Professor, Researcher, Scientist, Entrepreneur etc. .Selection of the Speaker will be made on the basis of the participant contribution in the respective research field. Each submission will be accepted based on the quality of abstract and conference sessions. Irrelevant submissions will be rejected. The acceptance and rejection of abstract submissions will be selected by the Organizing committee. All submissions will go through a procedure of quality checking by our team. Final approved abstract will consider for outstanding speaker awards.

The organising committee can avail in the process of managing the multiple tasks that need to be done. Committee members, having a good erudition of the event management plan, are well placed to provide training, supervision and assistance to other personnel involved in the organisation of the event. Meetings International will honour as a best OCM the individual who has demonstrated their support and guidance throughout the conference. OCM should be eminent or highly affiliated like Dean, Professor, HOD, Chair persons, CEO, CFO, MD etc. .Selection of the best OCM will be made on the basis of the participant contribution and years of experience in the respective research field. They must have good number of research papers and citations and should be more number of years of experience.

- Poster Size: Each poster should be approximately 1x1 M long. The title, contents and the author’s information should be clearly visible from a distance of 1-2 feet.

- Content: Use fonts such as Arial/Times New Roman in a reasonable font size that should be easy to read.

- The spacing between the lines should also be taken into consideration.

- A very simple format should be used representing all the details about the research carried by the author.

- Long narrated paragraphs should be avoided.

- Short phrases and bulleted points should be used in the poster to present the main highlights of the work done.

- Only abstracts submitted in English will be reviewed.

- Abstracts must not exceed 500 words (excluding the title, author affiliation and biography)

- Abstract should follow the instructions on the following template (Abstract Template).

- Do not include references or figures in the keynote abstract.

- Abstract should contain biography, photograph and short description about research

- Abstract must contain presenter name, affiliation and country

- Abstract title and abstract content should be relevant

Session 1: Advances in 3D printing & additive manufacturing

Advanced technologies for 3D printing and additive manufacturing and how these technologies have changed the face of direct, digital technologies for rapid production of models, prototypes and patterns. Because of its wide applications, 3D printing and additive manufacturing technology has become a powerful new industrial revolution in the field of manufacturing. The evolution of 3D printing and additive manufacturing technologies has changed design, engineering and manufacturing processes across industries such as consumer products, aerospace, medical devices and automotive. The objective of this book is to help designers, R&D personnel, and practicing engineers understand the state-of-the-art developments in the field of 3D Printing and Additive Manufacturing.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-2: Innovations in 3D printing

The world of 3D printing has the possibility of creating a newer, better future. From increasing the effectiveness of foreign aid to creating a more sustainable future. The possibilities presented to us by 3D printers have allowed us to imagine a better future. Unfortunately, the majority of objects that can be created are subject to the size of each respective 3D printer. Therefore, we can only print to a minimal extent. Alternatively, 2016 has seen an incredible advancement in the 3D printing sector. Below, we have curated a list of six innovations that will change the future of business and production.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-3: 3D printing materials

After over a year of research, countless filament spools, and hundreds of hours of printing, our team is proud to present the Ultimate 3D Printing Materials Guide. Covering over a dozen of the most popular materials in use today, this guide will help you select the best material for your next project or improve the quality of your prints with tips from our experts. Use the tags below to quickly sort the materials based on their characteristics, or view our extensive Filament Properties Table for a detailed side-by-side comparison. Once you have selected a material, view a detailed article with pros and cons, hardware requirements, best practices, pro-tips, example projects and more! Whether you’re new to 3D printing or an advanced user looking to experiment with a new material, this guide has everything you need to make the most of your next project.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-4: Impact of 3D printing on manufacturing industry

The world has seen many intriguing manufacturing technologies so far, however 3D printing has truly grabbed everybody's eye in the course of recent years. Not only does it have the potential to create something through an entirely unique process, but it also has the capability to render some production lines useless. If consumers are able to 3D print their favourite everyday consumer goods using a 3D printer at home, the manufacturing industries will face a serious drawback. On a different note, 3D printing has opened up new opportunities for production, factory maintenance, and R&D, since acquiring spares for a machine has never been easier. 3D printing is an innovation with a blended impression, however a great many people are seeing that the process will exceed the cons.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-5: Applications in health care & medicine

The method has been applied to (and used by) a wide range of industries, including medical technology. Frequently therapeutic imaging procedures, for example, X-rays, computed tomography (CT) scans, magnetic resonance imaging (MRI) scans and ultrasounds are utilized to deliver the first computerized model, which is in this manner sustained into the 3D printer.

It has been forecast that 3D printing in the medical field will be worth $3.5bn by 2025, compared to $713.3m in 2016. The industry’s compound annual growth rate is supposed to reach 17.7% between 2017 and 2025.

There are four core uses of 3D printing in the medical field that are associated with recent innovations: creating tissues and organics, surgical tools, patient-specific surgical models and custom-made prosthetics.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-6: 3D printing in biomaterials

3D Printing promises to create complex biomedical gadgets as per PC configuration utilizing patient-specific anatomical data. Since its underlying use as pre-careful representation models and tooling moulds, 3D Printing has gradually developed to make exceptional gadgets, implants, scaffolds for tissue engineering, diagnostic platforms, and drug delivery systems. Before 3D Printing can be used routinely for the regeneration of complex tissues (e.g. bone, cartilage, muscles, vessels, nerves in the craniomaxillofacial complex), and complex organs with intricate 3D microarchitecture (e.g. liver, lymphoid organs), several technological limitations must be addressed. In this audit, the significant materials and innovation propels inside the most recent five years for every one of the regular 3D Printing technologies (Three Dimensional Printing, Fused Deposition Modeling, Selective Laser Sintering, Stereolithography, and 3D Plotting/Direct-Write/Bioprinting) are described.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-7: Polymers in 3D printing

Polymers are macromolecules made of many rehashing subunits called monomers. These monomers are coordinated by covalent bonds where atoms share electrons being a strong union. The procedure to deliver a polymer is known as polymerization reaction. Thermoplastic polymers are really important in Additive Manufacturing. Thermoplastics are polymers which relax when they are warmed and harden as they cool. These polymers are utilized for plastic 3D prints, prominently Selective Laser Sintering (SLS). There are a few prominent thermoplastics that can be utilized with this procedure, delivering a variety of results depending on their base properties.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-8: 3D printing in space and aerospace

The airplane business incorporates a scope of business, modern and military applications, and is included pisions that plan, make, work and keep up the air ship or shuttle. Among the principal promoters of 3D printing, the airline industry is a driving force in the evolution of this technology for both manufacturing end-use parts and prototyping. Airlines depend on 3D printing to alleviate supply chain constraints, limit warehouse space and reduce wasted materials from traditional manufacturing processes. Rapidly producing aircraft parts on demand saves enormous amounts of space, time and money.

In fact, minimizing weight is the number one way that aerospace manufacturing companies save money because weight affects an aircraft’s payload, fuel consumption, emissions, speed and even safety.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-9: 3D printing in automotive industry

Since the early days, 3D printing in automotive manufacturing has witnessed unprecedented industry adoption. With the emerging economical and environmental concerns, there is a pressing need to rethink the way automobiles are designed and manufactured.

The automotive industry ought to adapt to this shift in paradigm quickly. This is where 3D printing in automotive design swiftly steps up. 3D printers not only help the aesthetic design of vehicles but it also has the prowess to deliver working prototype in record turnaround time. 3D printing in automotive design fosters innovation, creativity and limitless possibilities; empowering tomorrow’s transportation landscape.

Rapid Prototyping: One of the major benefits of 3D printers in automotive design is the empowerment of rapid prototyping in the pre-manufacturing stage. Companies have the possibility of developing everything ranging from scale-models right down to inpidual component, faster than ever.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-10: Additive manufacturing and 3D robotics

Additive manufacturing and robotics. One technology relies on steady, repetitive motion to build each infinitesimal layer, over and over again. The other technology is renowned for its repeatability and control. It's as if they were made for each other. It's a match made in disruptive technology, in the future of manufacturing.

Robots are not only enabling additive manufacturing, they're tending 3D printing machines (which are also robotic), automating AM post-processing, and allowing architects to envision new, flexible ways to build the world around us. Expanding our possibilities. These technologies are used to develop machines that can substitute for humans and replicate human actions. 3D robots can be used in many situations and for lots of purposes where humans cannot survive robots can take on any form but some are made to resemble humans in appearance in the acceptance of a 3D robot the approach of minimally invasive techniques in robotics, for the advent intervention.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-11: Digital Light Processing (DLP) 3D printing

DLP (Digital Light Processing) is a similar process to stereolithography in that it is a 3D printing process that works with photopolymers. The major difference is the light source. DLP uses a more conventional light source, such as an arc lamp with a liquid crystal display panel, which is applied to the entire surface of the vat of photopolymer resin in a single pass, generally making it faster than SL. Also like SL, DLP produces highly accurate parts with excellent resolution, but its similarities also include the same requirements for support structures and post-curing. However, one advantage of DLP over SL is that only a shallow vat of resin is required to facilitate the process, which generally results in less waste and lower running costs.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-12: Layered manufacturing and additive fabrication

Additive fabrication refers to a class of manufacturing processes, in which a part is built by adding layers of material upon one another. These processes are inherently different from subtractive processes or consolidation processes. Subtractive processes, such as milling, turning, or drilling, use carefully planned tool movements to cut away material from a workpiece to form the desired part. Consolidation processes, such as casting or molding, use custom designed tooling to solidify material into the desired shape. Additive processes, on the other hand, do not require custom tooling or planned tool movements. Instead, the part is constructed directly from a digital 3-D model created through Computer Aided Design (CAD) software. The 3-D CAD model is converted into many thin layers and the manufacturing equipment uses this geometric data to build each layer sequentially until the part is completed. Due to this approach, additive fabrication is often referred to as layered manufacturing, direct digital manufacturing, or solid freeform fabrication.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Session-13: Powder bed and inkjet head 3D printing

Among all 3D AM processes, regarding the material capability, powder bed inkjet 3D printing is theoretically able to form any type of metal, polymers, and ceramics as long as the material can be found in powder form with right particle size/shape and good flowability. The choice of binder/ink will be dependent on the material composition. There are two types of ceramic materials that are widely used and have been successfully commercialized with this technology, that is, plaster-based materials and refractory-based materials.

Powder bed inkjet 3D printing is one of the most traditional 3D-AM technologies that was invented in 1993 at MIT and exclusively licensed to Z-Corporation in 1995 [47]. Since then, the technology has been extensively used for fabrication of plaster-based ceramic material. In this process, the powder is spread in thin layers (usually 80 to 150 μm) on top of a solid platform and selectively bonded by the action of an inkjet print head, which contain a liquid binder or solvent. The process is repeated many times to build a 3D object layer by layer.

3D Printing & Additive Manufacturing Conferences | 3D Printing Conferences | 3D Printing Summit 2020 | 3D Printing Innovations | 3D Printing 2020 | 3D Printing in Robotics Conferences | 3D Bio printing Conferences | Bio printing Symposiums 2020 | 3D Printing Workshops 2020 | Printing Modeling 2020 | 3D printing Conferences 2020 France | 3D Printing Design & Engineering Conferences | 3D Printing in Medical Conferences | 3D Manufacturing Conferences | 3D Printing in Aerospace Conferences

Scope and Importance:

- The industry is being constantly driven by technological developments, which guarantee higher adaptability and empower faster design. Further, manufacturers have realized the advantages that 3D printing offers, such as optimizing material, labor, and transportation costs. Manufacturing units have had the option to eliminate material wastage using 3D printing.

- Governments over the world have just begun putting resources into R&D on 3D printing, which has positively affected on technology propagation and adoption. For example, the Dutch government put an extra USD 150 million in 3D printing-related research and development.

- However, the market remains constrained by high costs of equipment needed to deploy 3D printing on an industrial scale. The absence of a worldwide principles body directing producers likewise confines the market development.

Source of revenue and analysis of the 3D bio printing market:

- Bio printing materials

- 3D bio printers

- Services and ancillary equipment

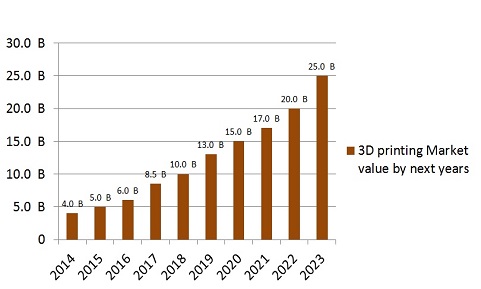

Market Growth of 3D Printing in the last and upcoming ten years:

Stratasys – Minneapolis, Minnesota, USA

Autodesk – San Rafael, California, USA

Hyrel 3D – Norcross, Georgia, USA

M3D – Fulton, Maryland, USA

Europe

3D Filaprint, UK

3D Gbire, UK

Addition Design, UK

Am 3D, UK

SLM Solutions, Germany

3D Hubs, Germany

EOS e-Manufacturing, Germany

Leap Frog 3D Printers, Netherlands

3D Print Pulse, Netherlands

Middle East

Advanced Manufacturing Services, Australia

3D Systems, Australia

IRIS 3D Solutions, Dubai

The 3D Shape, Dubai

3D PrintDXB, Dubai

3D Printing Industry, India

3D Print.com, India

Manufacture 3D, India

- Harvard’s School of Engineering and Applied Sciences, USA

- Princeton University, USA

- Cornell University, USA

- University of Tornoto, Canada

- University of Lethbridge, Canada

- University of Sheffield, UK

- University of Nottingham, UK

- University of Exeter, UK

- University of Melbourne, Australia

- University of Sydney, Australia

- University of Auckland, New Zealand

- University of Victoria, New Zealand

- Federal University of Santa Catarina, Brazil

- University of Nicosia, Germany

- Nanyang Technological University, Singapore

- National University, Singapore

- University of BITS Pilani, Dubai

- University of Indian Institute of Technology, India

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D-Tool Free Viewer

- Meshfix

Meetings Int. is a worldwide pioneer in delivering top notch gatherings, workshops and symposia in every significant field of science, innovation and medication worldwide receives 400,000+ online visitors with 1000+ sessions which confirm the outstanding pool of new users and visitors creating a platform to build your market place globally. Since its initiation, Meetings Int. has been related with national and global affiliations, organizations and elevated level people, committed to have world class meetings and occasions so its provide a big platform to show your product and advertise.

The explorer’s traffic is the benchmark for advertisement and the 3D Printing website is continually dragged in observer over the world. As specify by the Google Analytics, in excess of 50, 621 Researchers are visiting to our conference sites. 3D Printing conference help you to put the spotlight on your brand by advertising with more than 9 million+ readers worldwide and about 5 million+ hits every month on our site. We provide a good opportunity to boost your business on our platform. We offer a range of eye-catching advertising spaces and branding. Researchers from significant nations including United States, Japan, United Kingdom, India, France, Taiwan, and Germany visit our conference site. Subscribers and conference attendees can be your upcoming enthusiastic customers. We maintain high quality and ethical standards in event industry, which makes us unique and better than the rest.

Advertisement banner must be provided by the advertising company and must be in the jpg or jpeg format. The banner must be of high resolution and must not have copyright infringement.

For further queries, connect our Program Manager at 3dprinting@annualmeetings.net; contact@meetingsint.com

You can also connect us via WhatsApp: +65 3158 1626 / +44 1250 400 009

3rd International Conference on

3D Printing and Additive Manufacturing

July 22-23, 2020 | Paris, France

Young Scientist Awards at 3D Printing 2020 for the best researches in 3D Printing and Additive Manufacturing

Meetings International is announcing Young Scientist Awards through 3rd International Conference on 3D Printing and Additive Manufacturing (3D Printing 2020) which is scheduled at Paris, France during July 22-23, 2020. This 3D Printing focuses on “3D printing: The manufacturing technology that will change the world”.

3D Printing 2020 and upcoming conferences will recognise participants who have significantly added value to the scientific community of 3D Printing and provide them outstanding Young Scientist Awards. The Young Scientist Award will provide a strong professional development opportunity for young researches by meeting experts to exchange and share their experiences at our international conferences.

3D Printing focuses mainly on Advances in 3D printing & additive manufacturing, Innovations in 3D printing, 3D printing materials, Impact of 3D printing on manufacturing industry, Applications in health care & medicine, 3D printing in biomaterials, Polymers in 3d printing, 3D printing in space and aerospace, 3D printing in automotive industry, Additive manufacturing and 3d robotics, Digital Light Processing (DLP) 3d printing. 3D Printing conference operating committee is providing a platform for all the budding young researchers, young investigators, post-graduate/Master students, PhD. students and trainees to show case their research and innovation.

Eligibility:

Young Scientists, faculty members, post-doctoral fellows, PhD scholars and bright Final Year MSc and M.Phil. candidates. Persons from Scientific Industry can also participate.

Benefits: The Young Scientist Feature is a platform to promote young researchers in their respective area by giving them a chance to present their achievements and future perspectives.

- Acknowledgement as YRF Awardee

- Promotion on the conference website, Young Researcher Awards and certificates

- Link on the conference website

- Recognition on Meetings Int. Award Page

- Chances to coordinate with partners around the world

- Research work can be published in the relevant journal without any publication fee

Criteria:

- All presented abstracts will automatically be considered for the Award.

- All the presentation will be evaluated in the conference venue

- All the awards will be selected by the judges of the award category

- The winners of the Young Scientist Award will receive award certificate.

- The awards will be assessed as far as plan and format, intelligence, argumentation and approach, familiarity with past work, engaging quality, message and primary concerns, parity of content visuals, and by and large impression.

Guidelines:

- All submissions must be in English.

- The topic must fit into scientific sessions of the conference

- Each individual participant is allowed to submit maximum 2 papers

- Abstract must be submitted online as per the given abstract template

- Abstracts must be written in Times New Roman and font size will be 12

- Abstract must contain title, name, affiliation, country, speakers biography, recent photograph, image and reference

Conditions of Acceptance:

To receive the award, the awardee must submit the presentation for which the award is given, for publication at the website, along with author permission. Failure to submit the PPT, and permission within the designated timeframe will result in forfeiture of award.

Award Announcements:

Official announcement of the recipients will occur after the completion of 3D Printing Conference.

- 3D printing & Additive manufacturing

- Innovations in 3D printing

- 3D printing materials

- Impact of 3D printing on industry

- Applications in health care & medicine

- 3D printing in biomaterials

- Polymers in 3d printing

- 3D printing in space and aerospace

- 3D printing in automotive industry

- Additive manufacturing and 3d robotics

- Digital Light Processing (DLP) 3d printing

- Layered manufacturing & Additive fabrication

- Powder bed and inkjet head 3d printing

- Journal of Nanomaterials & Molecular Nanotechnology

- Journal of Fashion Technology & Textile Engineering

- Biomaterials and Medical Applications

9 Organizing Committee Members

18 Renowned Speakers

Aamer Nazir

National Taiwan University

Taiwan

Jens Bliedtner

Ernst-Abbe-University

Germany

Harley Stinson

Ulster University Magee Campus

UK

Larisa Zolotova

The State Hermitage Museum

Russia

Trenton Hall

LeTourneau University

USA

Andrea Barz

Ernst-Abbe-University

Germany

Laureana Stelmastchuk

IFSC Institute of Physics of São Carlos

Brazil

Amir Reza Shahbazkia

Girne American University

Cyprus

Tobias Rohrich

GEFERTEC GmbH

Germany

Sebastian Loewner

Leibniz University Hannover

Germany

Martin M Jin

Xian University of Architecture and Technology

China

Thomas Naze

University of Lille

France

Aamer Nazir

National Taiwan University

Taiwan

Ruben Foresti

University of Parma

Italy

Olaf Diegel

University of Auckland

Newzealand

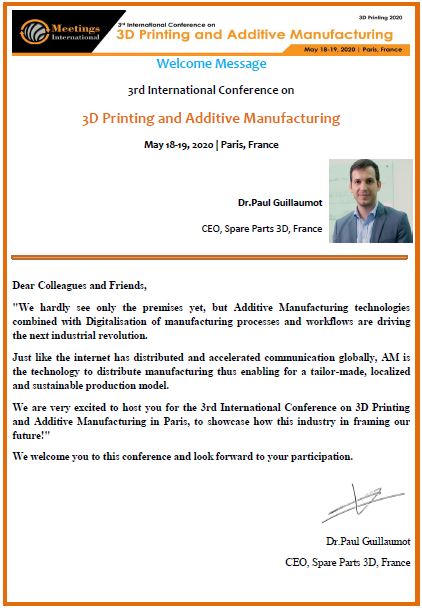

Paul GUILLAUMOT

Spare Parts 3D

France

Fahimeh Shahabipour

Pasteur Institute

Iran

David Sebastian Matamoros

National university of Colombia

Colombia